Measuring

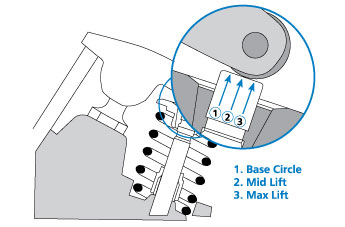

Valve train geometry is when the rocker arm tip moves from the intake side of the valve stem tip, across the center of the tip (at approximately mid lift), to the exhaust side of the valve stem tip (at full lift) and back. (SEE Diagram A)

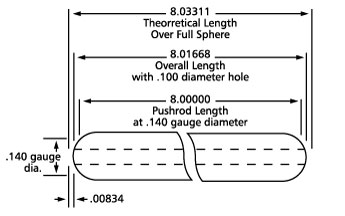

Pushrod lengths are measured starting at 0.140 gauge diameter, which means if you start at the center of the ball end and measure 0.070 in each direction (totaling .0140) then wherever this distance intersects with the radius of the pushrod is where the measurement is actually started. (SEE Diagram B) The rate of the radius will affect the overall actual length of the pushrod. The reason for choosing this measuring standard is that some manufactures have larger or smaller holes with different chamfers, and these factors will change the measured length.

Trend Performance manufactures all stocking and custom pushrods to the 0.140in gauge measurement.

Measuring

Two pushrods with the same actual 0.140 gauge diameter lengths but manufactured by different vendors may show different lengths.

Measuring results with a Trend Performance pushrod length checker:

Our pushrods length checkers are marked with a standard length which is laser etched into them. This number represents the gauge length of a part (0.140 gauge diameter) with the two halves tightly screwed together. Extending the checker one rotation lengthens the gauge length 0.050.For example, a pushrod etched 7.800 screwed apart one rotation would be: 7.800 + 0.050 = 7.850 gauge length. Therefore you would order the part number from the catalog based on this measurement.

Diagrams

Diagram A

Diagram B